| |

|

|

|

By Tachi Kiuchi and Bill Shireman

Lesson One: Use Limits to Create Value - Close the Loop

Skydiving is the perfect antidote for a high-stress job. It gives you total release. When you look down and realize that you are free-falling, straight for the ground, at 120 miles per hour, all your senses are fully engaged. There is little opportunity to dwell on corporate strategy, balance sheets, or day-to-day family issues. When people skydive, all their five senses must be operating effectively. Imagine, for example, that during this particular dive over Costa Rica, we had no sense of sight or hearing - just a sense of touch. With only a sense of touch, after we stepped from the airplane, we would feel the rush of the wind against our faces; we would sense great movement and exhilaration. It would be very exciting. The only problem is that we would not be able to see the ground, so we would have no way of knowing that we were descending rapidly toward it. We would not even know that we were falling. Thus the ground would have no impact on us at all, until we reached it. Then, it would have a significant impact. In business, we are much like a deaf and blind skydiver. Business operates with only two senses: taste and touch. Our businesses have a sense of taste in that we know what is going on inside the business - what our immediate bottom line is. And our businesses have a sense of touch in that we know the effect of what is happening directly to us from the outside, we feel it right now, this quarter. But think about it: Our businesses have no real sense of sight or hearing. We do not know what is happening at a distance, until it is directly affecting us, until we feel the impact. So we speed forward blindly, feeling the excitement of commerce, the exhilaration of the wind against our faces. But we do not know if we are ascending quickly into the sky or speeding toward the ground. Ray Anderson, the chairman of Interface Carpets, says that modern business people are often like the early inventors of airplanes, who pushed their homemade planes off the edges of cliffs, confident that once in the air they would fly. Many were surprised when they crashed to the ground. Ray says that we have pushed our whole economy off a cliff. We are rapidly consuming the earth's resources, cultivating a fast-moving economy. We feel the wind against our faces. Gravity is pulling us faster and faster, and we feel more excitement than ever. But now we are approaching the ground. Before we reach the ground, we need to wake up. We have work to do. While we are in midair, falling, we must - as the rainforest has - learn to slow our fall, or even to reverse it and fly. In the Rainforest: Feedback Triggers the Creation of Value Feedback Is Nature's Way to Learn In the rainforest, the evolution of every creature is

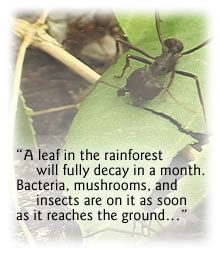

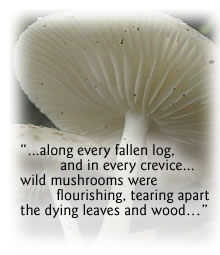

shaped by feedback, adaptation, and learning. Every species is sculpted

in response to the extreme limits that are a constant reality. These

limits propel the creatures of the forest rapidly toward a "ground

zero" at which they have fully consumed the resources that had

sustained them. However, through feedback and The rainforest delivers these resources through an extensive array of feedback loops that serve as the sensory system of the forest. These loops are extremely tightly bound, compared to those of temperate forests. In Pacific Northwest forests, for example, warm spring days signal plants to burst with buds, shoots, and leaves, creating an environment rich in protein. Animals conditioned by this protein pulse bring forth their young during this time; birds return to raise their newborn, insect eggs hatch, frogs awaken from hibernation. In summer, plants and animals tap the abundant food to grow in size and number. Come autumn, growth slows, trees drop their leaves, and plants produce berries, seeds, and nuts to reproduce again in the spring and to sustain life through the winter. In the tropical rainforests we visited, by contrast, sunlight, rain, and warm temperatures are constant, and plants germinate, grow, flower, and seed year-round. Leaf fall is slow and continuous, rather than concentrated in the fall. As a result, there is no seasonal protein glut. Constant heat and moisture lead to fast decomposition. The humus that enriches the soil in temperate forests doesn't have time to accumulate in the tropics. The forest floor is a dark factory of decomposition. A leaf that falls in a North American forest may take a year to decompose; the same leaf in the rainforest will fully decay in a month. Bacteria, mushrooms, and insects are on it as soon as it reaches the ground, or before, tearing it into nutrient molecules, liberating them to be drawn up into roots or leached quickly from the soil by rain. In Costa Rica, it seemed that at the base of every tree, along every fallen log, and in every crevice where forest litter could gather, wild mushrooms were flourishing, tearing apart the dying leaves and wood and returning their components to the soil as rapidly as possible. Here in the tropics, root systems find water and nutrients close to the soil surface, so these root systems are shallow. Roots may barely penetrate the soil, or they may even run along the top of the ground. Such shallow root systems can leave tall trees vulnerable to wind or weather that could topple them. To keep them upright in the absence of a deep root system, many tree species grow side buttresses - thin, hollow flanges that extend from the base of the tree to the ground like the legs of a Christmas tree stand. These supports sprawl outward across the forest floor, like a vacuum system that draws in resources and delivers them to the rich canopies of life above. The processes of breakdown and buildup in living systems are called their metabolism. Within every living system, from a forest to a cell, raw materials are drawn in and broken down into simpler forms in a process biologists call catabolism. Then, inside each cell, enzymes, cellular factories, or other agents take the pieces and rearrange them in more complex forms - a process called anabolism. In this process, certain values are lost, traded for new ones that yield a new whole. In other words, new resources are gained as others are lost. In the forest, resources are drawn up from the soil into the roots of trees and plants and delivered to a vast array of species. Biologists used to diagram this arrangement by relating species to one another in a manner so simple that they resemble linear food chains, each link reliant mostly on one or two other links. This simple kind of diagram has, of course, been used to depict the way we convert resources to industrial products. However, this approach, even when used in scientific journals, vastly understates the diversity and interrelationships of species. If all forest forms of life were linked together in simple food chains, they would quickly run out of resources. Conversion rates are extremely low: Often 1 percent or less of the caloric content of one link is converted to calories by the next. For example, plants convert into energy no more than 2 percent of the sunlight that reaches them. Sheep that eat grass or cows that eat corn keep about 1 percent of that. People that eat the sheep or the cows keep 1 percent of that. This entire three-link food chain ends up "wasting" 99.9998 percent of the original energy of the sun. How does nature overcome such extreme wastefulness? By drawing species together in complex food webs. Food webs offer major efficiency gains over simple food chains. In a web, energy "wasted" in one process isn't really lost. It just shoots off to the side, where nature tends to put it to its best local use, in whatever form it's in. Thus webs contain vastly more connections than classic descriptions of food chains. Most species eat or are eaten by ten to 1,000 other species. Resources cascade through the web as they are transformed back into their simplest forms and are drawn back through the web again as they meet and combine with other resources to take on more complex forms, in an endless nonlinear flow. The resources do not usually cycle back into the same forms, since that would require the consumption of more energy to transport and reform them. Instead, they are taken up in their present form, to fill a local need to which they are already suited. Machines Just Do It - Living Systems Also Improve It The strands in these webs aren't static like those in a spider's web. They are dynamic passageways that in effect draw all the organisms in a forest together into a single coextensive network, Tansley's ecosystem. Competition, which forced the adaptations in the first place, now undermines its own position and partially gives way to cooperation. Everything begins to rely on everything else for the efficient and effective operation of the whole. As the linked strands in simple food chains branch off

in all directions to form webs, feedback and adaptation accelerates.

Food webs find ways to use all the resources consumed within them. With

every new feedback loop, new arrangements are made, over time leading

to the development of new relationships, even For example, in simple food chains, resources are taken in at one end, used in the middle, and discarded as waste out the other end - to the "outside," that is, to the next larger ecosystem. Food chains act more like simple machines: When they are receiving fuel, they keep performing the same task, repetitively. When the fuel runs out, they stop. They lack the options of a more complex system, so they are less able to adapt. Food webs, in contrast, have lots of options. They act not as machines but as complex adaptive systems with the ability to sense resource supply levels and adapt to subtle shifts as they happen. In complex food webs, all waste is food. However, this recycling isn't direct. In the forest, nature doesn't waste energy turning leaves directly back into leaves. She takes them as they are. Leaves may become mulch, then break down into their chemical components, each of which is taken up in new processes. Like the organisms they previously constituted, they feed or are fed by many subsequent processes. Nature also follows this strategy on much larger scales. Look, for example, at how nature recycles water through the hydrological cycle, the natural circulation of water between earth's surface and the atmosphere. Water evaporates from the oceans. From there, air moves the water to cooler realms where it condenses into clouds. Then the clouds drop the water back to earth through precipitation. Once it reaches the ground, it spreads out and joins rivers, streams, and soil. From there, it may be taken up into plants and animals, many of which are at least 95 percent water. Then, the water may be broken down into hydrogen and oxygen and reassembled with other atoms such as carbon to form carbon dioxide and other compounds. Because water serves functions at every stage along the way, the "transportation costs" of water recycling are, in an important sense, zero. The entire contents of the world's oceans would take about one million years to pass through the water cycle, but this does not mean nature is slow - it means nature is thorough, complex, and yielding. This fact points to a flaw in conventional wisdom about recycling. Often, environmentalists and business leaders seek to "close the loop" by recycling a given product back into the same product - a can into a can, a box into a box, a car into a car, for example. That's fine, but simple closed recycling loops can be inefficient. If a product is consumed far from where it is produced, for example, the energy costs of getting that product back to the point of production can wipe out the environmental gains of recycling. Yet when one product is recycled into a different one, especially a less valuable one, environmentalists sometimes criticize the process as "downcycling." Sometimes they are right: If a high-value application is locally available, then a low-value use of recyclables may be wasteful. But often "downcycling" is simply the most efficient way to use resources. Consider, for example, the crude ways we have been recycling most plastics. Plastic bottles of milk or soft drinks are placed in recycling bins, transported to local service centers for sorting, transported to centralized facilities for grinding. Then they undergo three separate, energy-intensive processes to prepare them for remanufacture back into bottles. Each process imposes additional environmental costs, as the empties are shipped cross-country from one process to the next. The components of the bottle are of value only at the beginning and the end of the process. The entire chain that takes them from the home back to the factory imposes costs, both economic and environmental. It can take more energy and materials to recycle a plastic bottle back into a plastic bottle than to make a brand new one. By comparison, if plastic bottles are refilled or recycled as fabric for clothing or carpet, reprocessing steps are reduced, costs are lower, and less energy and pollution is created in the process. Plus, a handful of companies, such as C&A Floorcoverings, can recycle the end product yet again. So, nature's strategy for recycling is to build local markets, using materials as it finds them, at or near the point where they are created. In this way, the path of resources through nature's economy grows more and more complex, less like a food chain, and more like a food web. In Business: To Create Value, Harness Feedback - Close the Loop Bill Coors and the Closed Loop: Business-as-Living-System The first step in turning an inefficient food chain into

a rich food web and fostering a vibrant productive economy is to close

the loop. In so doing, nature takes a simple machinelike system, one

without the Closing the loop is a core strategy that Bill Coors, Chairman of Adolph Coors Company, has used for many years to awaken machinelike companies and turn them into more adaptive, living companies, able to learn how to grow more efficient and innovative year by year. By feeding back the environmental costs and benefits of doing business, he has triggered a series of efficiencies and synergies that have enabled both his companies and their stakeholders to profit. Feedback is a source of information, says Coors, and it takes two forms. Soft, gentle feedback cultivates easy adaptation. Hard, powerful feedback forces painful adaptation, or death. Coors prefers the soft, gradual path of adaptation. He has learned that by triggering early, subtle forms of feedback, he can stimulate both continuous and discontinuous change at his companies and keep them a step ahead of trends that buried most of his one-time competitors. Bill first met Bill Coors in 1985, in his office adjacent to his brewery in Golden, Colorado. We were supposed to be on opposite sides in a bitter environmental battle. I was CEO of the nation's largest recycling lobby at the time, fighting for a California "bottle bill" that would require deposits on beer and soft-drink cans and bottles. Coors was head of the nation's number-three brewery. I was preparing my organization to mount a second statewide initiative campaign for a bottle bill, an effort that Coors and his allies would have invested millions to stop. Yet Coors turned out to be our most powerful ally, not for a traditional bottle bill but for a new, more effective form of the law that we designed and that California passed into law. The law has historically recycled nearly 80% of bottles and cans, according to Darryl Young, director of the California Department of conservation. California's version of the bottle bill applied a philosophy Coors had used to create profits at the brewing company and a host of spin-offs: "All pollution and all waste is lost profit." Coors knows that in business, pollution and waste are stuff the company has paid for but can't sell. He also knows that the costs of pollution and waste extend far beyond those the company pays directly. Even before biologists described to him the ecological effects of can and bottle litter in the hills around his brewery, Coors had been on a mission to reduce waste and recycle everything the company made. As can most industrial companies, Coors Brewing can be seen as a value chain of related suppliers and customers, a linear, industrial food chain. Raw materials are extracted or grown by producers, processed by a succession of suppliers, then purchased, processed, and packaged by Coors to create and deliver its final product - beer in packages that are quickly used up and thrown out. Being structured like a food chain can be highly profitable as long as you aren't stuck at either end of the chain, where resources are taken or wastes thrown away, where costs are externalized. Brewers and most other profitable companies enjoy their position in the middle of the chain. That is understandable: They get to pass those external costs on to the environment or society and keep many of the profits for themselves, as long as no one balks. But eventually, as those unaccounted costs rise, someone objects. While most other brewers saw in their success a sign that they could grow forever, by the late 1950s Bill Coors was convinced such growth was not sustainable. The Achilles heel of the industrial economy, Coors says, is the linear system that is its principal profit driver. Industrial companies in essence take raw materials and fuels from nature, cycle them through the economy as products, then throw them away as garbage. Coors calls that an "open loop" system, a linear food chain that exploits nature's resources and leaves only waste at both ends. Such open loop systems might work in the short term, but Coors believes no economy can last forever if it systematically depletes its sources of supply. In the end, Coors believes, the open loop will have to be succeeded by what he calls a "closed loop" economy, one where the full array of costs is accounted for within the system, quickly and gently. That way, companies and consumers would be rewarded for reducing them. In a closed loop system, the costs of any action are fed back promptly to the person or company in the best position to reduce them, before they build up and impose great pain. Assigning blame isn't the point. Since resources flow in cycles, finger pointing always leads back to the accuser. Instead, each link in the system must learn to respond to soft, gentle forms of feedback, adjusting its behavior to reduce costs to the whole. Of course, laws are sometimes needed to create incentives for this approach. The person responsible for a cost and the one best able to reduce the cost are not always the same. Because many still insist on assigning blame as well as responsibility, laws often take a punitive form. These are difficult to pass and often unnecessarily costly when implemented. Simply dropping issues of morality and focusing on practicality would do much to unify business and advocates. Bill Coors wanted to create a closed loop system at Coors with zero waste as a goal, decades before it became fashionable, and he invested in programs to achieve it. Coors found the closed loop concept - through feedback - to be a powerful driver of two kinds of value that we will discuss at depth in a later chapter: efficiencies and breakthrough innovations. To create the new system, Coors decided simply to target costs and enhance feedback. As open loops were closed, the company's simple value chains would begin to take the form of innovation-inducing value webs. As in nature, these webs would stimulate a cascading series of effects to increase adaptation, hone specialties, harness diversity, promote excellence amidst complexity, build cooperative alliances, and create emergent value through synergies. How? Driven by the closed loop ideal, Coors first stimulated a wave of innovations founded on efficiency. To control liquid waste from the brewery, Coors built Colorado's first biological water treatment plant in 1952. He offered to treat all sewage from the city of Golden as well, a partnership that endures almost 50 years later. The investment made little sense from the short-term profit perspective of Coors Brewing, but it was clearly the least-cost path for the community as a whole, so Coors took it. He could do that back then, he says. The company was privately held, so covering extra costs wouldn't run counter to their shareholder responsibilities. He also formed environmental task forces, set goals ("zero waste, zero emissions"), and launched a series of programs designed to eliminate waste from Coors operations. No waste stream was spared. Spent grains became fertilizer and feed. Organic waste was sold as compost. An improved internal accounting system tracked every use of toxic materials, triggering new innovations that led to an 80 percent reduction. Coors even found a way to eliminate the solvent-based inks that other manufacturers still use to decorate their cans. The company invented an ultraviolet process that cured inks in less than a second and cut ink consumption as much as 90 percent. That eliminated the energy-hungry ovens that previously took two minutes to dry solvent-based inks. Among environmentalists, however, Bill Coors is best known as the father of aluminum recycling - and hence of much of the residential recycling that has blossomed over the past generation, since its costs are often largely borne by revenues from aluminum. His fascination with recycling was triggered in 1957 by a chance encounter with a local environmentalist, Dr. Beatrice Willard, who taught biology at the University of Colorado. Dr. Willard led Coors on a trail in the forest tundra surrounding Golden. She showed him the empty bottles and cans and explained the effect they were having on the tundra ecosystem. That got Coors thinking: if he could buy back those cans and recycle them, not only would the litter problem be reduced, but he would have a continuous supply of packaging materials. Coors went back to the brewery and penciled out a program to offer consumers a penny for every Coors can they returned for recycling. The collection program was an overwhelming success. More cans came back than anyone had projected, millions more. The problem was that the aluminum companies wouldn't take them back, and Coors had no way to recycle most of them on its own. So, as millions of cans were stockpiled at Coors' Golden brewery, Bill Coors spent millions of dollars to launch his own development effort. He refused to buy aluminum from companies that wouldn't take it back for recycling. He end-ran the aluminum companies by developing a "continuous casting" system for can making that cut costs and could use almost 100 percent re-cycled aluminum. And he opened the nation's first aluminum recycling centers offering "cash for cans." Coors even developed a concept for a national law requiring returnable beverage containers. Called the "Closed Loop System," it became the first draft of what we later used as our model when we designed California's beverage container recycling law. But Coors found another source of profit that may be even more environmentally sustainable and financially lucrative than efficiency. That source is breakthrough innovation. Coors' source for these breakthroughs comes from the designs of nature. According to Coors, value doesn't come from physical resources per se, but from their design. All fossil fuels and other raw materials are made of the same fundamental components. It is the design of these resources, not simply their physical content, that gives them their value. Similarly, businesses don't create value by consuming materials but by combining them into forms that yield new qualities. Coors taps this kind of value at two of the other companies he founded: CoorsTek and Graphic Packaging. For example, CoorsTek - now the largest U.S.-owned manufacturer of advanced technical ceramics - uses smart design, not additional materials, to embed hardness, strength, insulation, and durability into its products. Graphic Packaging uses ingenious technology to cut ink use as much as 90 percent and solvent use 100 percent, at the same time producing bolder graphics. CoorsTek and Graphic Packaging couldn't be more different from Coors Brewing. Rather than making one product for a mass market, they make 10,000 different products that fit very precise market niches in 23 of the 24 defined business sectors. In the past, they made everything from high-tech ceramics to solar cells to organic plastics. Products that found market demand were kept-selected, to use the genetic parallel. Those that didn't were eventually sold or dropped. Today, CoorsTek's engineered materials are used for everything from computer hard drives and mobile phones to on-board auto electronics, to fuel cells used in experimental hypercars. Graphic Packaging makes some of the most environmentally resource-efficient packaging in the consumer market. Both companies create value by following Coors' core philosophy: All waste is lost profit. Eliminate everything that doesn't deliver value, and you can maximize both economic and environmental performance. First, Ford's Machines Foment a Revolution: Then, Feedback Triggers the Evolution Bill Coors credits Henry Ford with developing the open-loop

machine model for business. At the time, it was a powerful agent for

progressive change. Henry Ford, who founded Ford Motor Company in 1903,

was not just a capitalist seeking to maximize return to shareholders.

Uninspired routine goals like that Ford had a mission. He knew that machines embodied human genius; they were ideas expressed in design. He saw the machine as a magnificent instrument, created by ingenious design, that distributed value widely throughout society. Because they could take the genius of one individual and deliver it to millions, they carried with them the capacity to create equal opportunity and eradicate ignorance and poverty. They would enable people, in the words of visionary designers Charles and Ray Eames, to "get the most of the best to the most for the least." Value is created when an idea - a particular machine design: the printing press, the assembly line, the microprocessor - is formed in one's mind. That's breakthrough innovation. Once proven, the idea is like a bank into which a large deposit is made. All great inventions in effect put vast amounts of money in society's bank - and sometimes, of course, take money out as well. How do you draw on the created value? First by applying the idea. Initially you may apply it in one big way. Later you create variations on your core idea - you refine it and apply it in many smaller ways. You design better printing presses; you customize the assembly line for many kinds of products; you embed computer chips in watches, daily planners, cars. This process of refining, varying, and improving an idea is continuous improvement. But the source of any gains is not in the materials, it's in the ideas. Obviously, once an idea is applied in a physical way, matter then embodies the idea; the materials contain the value, but they aren't its source. Matter is like paint to the painter; it is neither the source of value nor the inspiration, but only the medium to express it. Ford's vision, his breakthrough innovation, was to use machines to make machines: Machines to make his parts, machines to run his assembly line, in a horizontal arrangement that substituted machine work for muscle. His workers too he used as machines. He even organized the workers in a machinelike institution, a top-down industrial hierarchy, with brainwork removed from the local level and centralized at the top, an approach that became the dominant model of industrial management for much of the 20th century. Through these efforts, Ford created a manufacturing system that radically reduced the costs and expanded the output of the early automobile industry. Ford's crowning achievement is well known. The automobile assembly line, and all the innovations that enabled it, so streamlined the process of automobile manufacture that it led to the explosive growth of the product line; indeed, he triggered the industry's greatest period of growth. By using precision-made standardized parts and moving them to workers along an assembly line, Ford increased labor productivity by a factor of four or more. Because workers no longer needed to walk from car to car or file down individual parts to fit, the amount of labor required to make a car dropped from 12 hours to two and a half. Ford's economies of scale delivered a Model T to consumers for $360, compared to competitors' $850. By 1914, Ford was making nearly as many cars as his 300 competitors combined, with a fifth as many workers. Thus Ford's breakthrough - his assembly line system - was so efficient that it drove down the cost of cars, leading to dramatic boosts in his volume, the economic equivalent of replication. Ford's sales success led in essence to the company's selection by the economy and forced his competitors to either adapt in response or leave the market. Ford carried the genius of the machine to the structure of work itself. Instead of relying on trained craftspeople, he reorganized production so that each assembler had only a single task, one which required at most a few minutes of training. As a result, he could bring together workers from widely divergent cultures and backgrounds. The need for a common language among workers became irrelevant: They had no need to talk to one another at all. Economically, Ford's assembly line was a breakthrough innovation. It did not merely refine the craft of automobile making, shaving off a little waste here and there; it revolutionized the business and brought a huge gain in efficiency. But was Ford's assembly line itself efficient? Yes, but only by comparison to the craft system it replaced. It was far from the most efficient that an assembly line system of manufacture could be. As is any prototype, Ford's breakthrough was now ripe for its own series of improvements. The relationship of breakthrough innovation and continuous improvement is an important distinction to remember. Breakthrough innovations often bring radical gains in effectiveness, much greater than incremental improvements in efficiency of an older process. But in their early forms, these innovations are like prototypes, crude and imperfect, requiring continuous improvement. Ford's machines - and the machine style of management he championed - were powerful and progressive tools in their time. However, machinelike forms of management are neither unnatural nor undesirable in an absolute sense. They are a necessary (and perhaps universal) stage of industrial development. They play their roles as agents for mass production, but they are only one form of management. If not blended with others, they can be expensive. One of the most significant costs of the assembly line was a human cost. By removing brainwork from the factory floor and centralizing it at the top of the machinelike structure of the business, Ford ultimately undermined the resilience of his design. His system lacked a quality essential to long-term sustainability: the ability to foster dynamic, continuous change and improvement. As a result, Ford was slow - very slow - to develop a manufacturing system with the capacity for learning and continuous improvement. Ford's competitors corrected the imbalance. These competitors pioneered changes that took Ford's breakthrough and institutionalized within it a system of continuous improvement. Later, the leading proponent of the changed system, W. Edwards Deming, and his colleagues, such as J Deming, and his colleagues, such as Joseph Juran and Kaoru Ishikawa, became the champions of quality management and learning organizations, companies with the capacity to learn and improve by doing. Formal systems of feedback kept workers aware of how well objectives were being met. Formal and informal relationships among employees allowed them to identify and solve problems on their own. While most objectives were necessarily centrally set to meet the needs defined by the market and stakeholders, the methods used to meet the objectives were often selected by the workers who performed the tasks. To Deming, this system of feedback was vital to improving quality and productivity. He believed that the workplace is a learning community, a campus, where people are motivated by the ability to apply their own intelligence and skill. Power in a Deming organization is decentralized; people work together in teams and networks. Hierarchies are relatively flat, and leadership is held by those able to facilitate functional relationships between formal and informal teams of specialists. The most valuable forms of capital in the learning organization are knowledge, gained through feedback and learning, and changes in design - that is, adaptation. Workers are a vital, engaged part of the production process; they learn what's working, and what's not, and they apply their knowledge to continuously refine and improve products and processes. Achievement is motivated mostly by the recognition and appreciation one receives from colleagues and team members. Status is accorded by one's specialty and how it advances the performance of the team as a whole. Toyota mastered Deming's methods and refined them using the ideas of Shigeo Shingo and Taichi Ohno, who developed the company's famed production systems in the 1950s and 1960s. Ohno thought, why hire outside experts to reengineer production processes, as Henry Ford did, when you have workers who study and know the system through experience, every day? Instead of just hiring outside experts, Toyota used their own home grown ones. By 1982, workers were making nearly two million suggestions a year, more than two every month per employee, and 95 percent were implemented. Thus was developed kaizen (ky-zen), Japan's learning organization system that creates value through continuous improvement by everyone from executives to managers to workers. Kaizen identifies costs and inefficiencies before products even leave the factory and feeds that information back at the design stage, closing the loop. Machines multiply the worker's muscle; kaizen rediscovers the value of the worker's mind. According to management consultant Masaaki Imai, "Kaizen strategy is the single most important concept in Japanese management - the key to Japanese competitive success." Today, Ford Motor Company is also applying the lessons of kaizen. Chairman and CEO William Clay Ford, Jr.'s strategy is to make Ford a "consumer-focused company," super-responsive to both broad and subtle consumer desires, by feeding marketplace information back to the design level. As devoted a social activist as his great-grandfather, Bill Ford's personal mission is for people to feel that the world is a better place because Ford is in it. When the company recalled 20 million Firestone tires because of safety problems in 2000 and 2001, Ford believed the company's best strategy was total openness. As former CEO Jacques Nasser played the leading public role, Ford worked with the board of directors and shareholders to carry out the company's response in full public view. Bill Ford remains a step ahead of his colleagues, even at his own company. The result: "Ford is two companies," says Corporate Governance director Deborah Zemke, one of Bill Ford's designated internal activists. The first company is today's Ford, a main line automaker that makes low-mileage SUVs. The second Ford is the company it aspires to be, the one that makes the best-selling high-mileage car, the Focus, plus battery electric cars, closed community vehicles, and electric bikes. It is revamping its historic River Rogue factory complex using design concepts of ecological architect William McDonough. It rates its own performance on sustainability and publishes the results annually. Bill Ford thinks electric vehicles are a better option, but their next generation won't just be traditional cars with electric engines. Ford thinks the new electrics may be strikingly different, redesigned from the ground up. Under the "TH!NK" brand name, Ford makes three types of electric vehicles: an electric bicycle, a neighborhood car, and a city car. The TH!NK traveler is an electric bicycle that folds so that riders can carry it on transit systems and into the office. The brand name Th!nk gives a clue about Ford's approach to the future. The key to Bill Ford's success is the company's openness to feedback and its ability to learn and adapt in response to it. To stay ahead of the market, Ford must be a living company. And the core resource that can make that a success is information. Purchase their book What We Learned in the Rainforest: Business Lessons from Nature. Tachi Kiuchi is the former Chairman and CEO of Mitsubishi Electric America. He helped make household names of such brands as Mitsubishi and MGA. Bill

Shireman is the founder of The Future 500. He writes and speaks about getting past our polarization and about how companies can profit from sustainability. |

|

Home | History & Archive | Video Productions & Services © Copyright 1998-2023 EcoIQ |

[Editor's

note: The excerpts below are from an important new book -

[Editor's

note: The excerpts below are from an important new book -  feedback

to "close the loop," triggering innovations that lead to new

products, processes, businesses, and profits.

feedback

to "close the loop," triggering innovations that lead to new

products, processes, businesses, and profits. adaptation,

they develop a system that brings new supplies of resources - the margin

they require to avoid hitting the ground - often just in time.

adaptation,

they develop a system that brings new supplies of resources - the margin

they require to avoid hitting the ground - often just in time. new species. With every adaptation, the information content of the ecosystem

increases; in effect, ecosystems learn.

new species. With every adaptation, the information content of the ecosystem

increases; in effect, ecosystems learn. immediate

capacity to sense costs and adapt, and awakens it gradually into a more

adaptive and resilient complex living system.

immediate

capacity to sense costs and adapt, and awakens it gradually into a more

adaptive and resilient complex living system. would

have bored him. He was a social activist, with a cause as elevated and

progressive as any that motivates today's activists.

would

have bored him. He was a social activist, with a cause as elevated and

progressive as any that motivates today's activists.